Save 16 + hours per main‑gear change

side & drag stays remain fitted, so preparation and rigging steps vanish.

Ground‑based, all‑electric control

no cranes, no on‑wing work, just two engineers and an 8″ HMI touchscreen for precise joystick moves.

One tool, every wide‑body

adaptors cover A330/A340, A350‑900/‑1000, A380, 777 (incl. X) and 787 families.

Overview

LGX MultiSystem is RH Aero’s next‑generation, pallet‑shippable trolley for main‑landing‑gear R/I. An electric X/Y/Z drive, digital‑twin support and single‑operator HMI turn a high‑risk, crane‑intensive job into a fast, repeatable ground‑level procedure that protects staff, airframe and schedule.

Details

- 8″ touchscreen + three joysticks with wired or wireless operation for millimetre‑accurate moves.

- Tool‑Centre‑Point logic lets the operator set one fixed pivot, so the gear never drifts.

- Digital twin for VR training, live load‑cell read‑outs and remote diagnostics.

- IP54 / CE / UL rated electronics for indoor or apron use.

- Ships worldwide on a single ULD pallet – no exceptional transport needed.

Product Scope

Airbus | Boeing |

A330 family | 777‑200 / ‑300 |

A340 | 777‑8 / ‑9 (X) |

A350‑900 / ‑1000 | 787‑8 / ‑9 / ‑10 |

A380‑800 |

Additional adapter validations in progress.

16.10.2025

RH Aero together with EFW validates LGX MultiSystem on Airbus A330

Elbe Flugzeugwerke (EFW) and RH Aero Systems have successfully performed the A330 on-aircraft validation of the LGX MultiSystem during a passenger-to-freighter (P2F) conversion.

08.07.2025

RH Aero and BAMC - First 787-8 MLG Change with LGX MultiSystem

British Airways Maintenance Cardiff (BAMC) has successfully performed a main landing gear change on a Boeing 787-8 Dreamliner using the LGX MultiSystem, RH Aero Systems’ fully electric, ground-based landing-gear change system.

Technical Data

Movements

Longitudinal (X-axis) | Unlimited |

Lift (Z-axis) | 1,550mm / 6.1in |

Transverse (Y-axis) | ±200mm / ±7.87in |

Yaw | 24° (+/-12°) |

Pitch | 3° nose down, 15° nose up (+2° extra) |

Dimensions

Width | 2,400mm / 98.5in |

Length | 4,900mm / 193in |

Height (min.) | 1,100mm / 43in |

Capacity and Weight

Load Capacity | 4,400 kg / 9,700lbs |

Weight | ~6,000kg / 13,228lbs |

Drive

Electrical Driven | 3/PE AC 380-420 V 50 Hz 3/PE AC 440-480 V 60 Hz |

Talk to an RH Aero │ HYDRO specialist about lead‑time, pricing and ROI for the LGX MultiSystem Universal Landing Gear Change System.

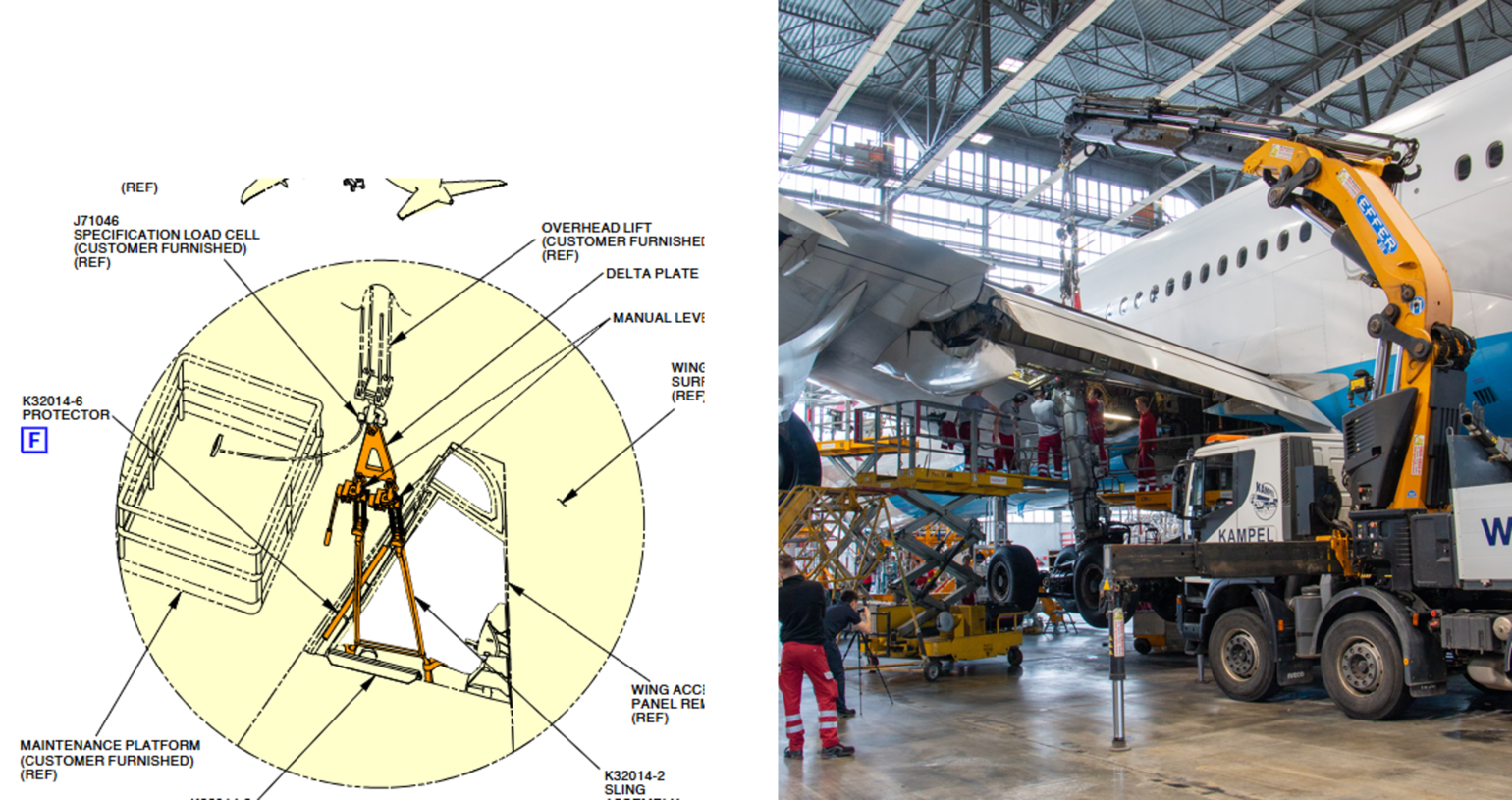

Traditional Process

- Overhead sling/crane method

- Wing top skin to be removed

- Controlled movements not possible

- Risk of damage to gear and airframe

- High manpower required to control movements

LGX MultiSystem Process

- Ground based method

- No need to remove wing top skin*

- Gear always in fully controlled position

- Significant reduction of risk of unintended movements

- Less manpower required (1x tool operator + 1x trunnion pin R/I)

* A350 & B787: avoiding top skin removal requires LGX-compatible actuator R/I adaptor (development in progress)

Customer Story

British Airways Maintenance Cardiff proves the LGX advantage

During a 12‑year heavy check in July 2025, two BAMC engineers completed a Boeing 787‑8 main‑landing‑gear change with the LGX MultiSystem and no overhead crane. Real‑time load‑cell monitoring kept bearing loads within AMM limits, while side‑ and drag‑stay assemblies remained fitted, eliminating a major removal/re‑installation sequence and cutting man‑hours dramatically. Engineer Richard Langdon summed it up:

“The gear never moved unless we told it to, so the job felt far safer and more controlled than the conventional method.”

Business impact

BAMC released the Dreamliner back to the flight schedule sooner, generated additional hangar capacity for parallel projects, and lowered both labour and tooling overheads — all while improving safety margins with real‑time load‑cell monitoring and fully controlled, ground‑based movements.

Field experience on the first 787‑8 gear change shows a double‑digit hour reduction because side‑ and drag‑stays stay on the landing gear and no crane rig‑up is necessary.

Adapters for Airbus A330, A340, A350‑900/‑1000, A380‑800 and Boeing 777 (all variants) plus 787‑8/‑9/‑10 are qualified, with further validations under way.

No. The ground‑based trolley keeps the gear fully supported, so wing‑skin removal is avoided on 787 and A350 models.*

* A350 & 787 actuator work: avoiding top‑skin removal requires an upcoming LGX‑compatible actuator R/I adapter (development in progress).

Yes — the base unit is IP 54‑rated and CE/UL‑compliant, making apron or remote AOG work possible.

RH Aero offers blended courses: Trainings simulation via the digital twin and hands‑on sessions at the Biberach Test & Training Centre.